Have you been attempting to address your chooks, ducks or another flapping pet? We are sure, for folks out there who love birds - and honestly what can be more musically peaceful than a wild bird kaleidoscope.. We all know the joy of watching your favorite pet anthorring chirping sitting on upper side or in that ideal nest. To accomplish that, one of the best practices is to have exhaust fans in your farm. Why does that matter to you? This is because of the fact that cleaner air = healthier your bird and only an exhaust fan does this.

Air quality is simply how clean or safe the air we and other living things (including your birds, of course) breathe. Because it is very hot inside the chicken farm, or also by humidity in air contamination caused particles emitted by feeders and water fountawns of birds Loewe more gases ammonia from faecal remains decomposing onrestrial floor where chickens are raised. All those stuff can not only make your birds fall ill but also they might hurt its eye or it may even lead to death. Therefore, a great responsibility is carried out to keep your birds air quality properly.

So the benefit of healthy life and safety remains with your birds, you must keep running fresh clean airs into your farm always. This is where an exhaust fan comes in to rescue. The exhaust fan will pretty much suck out the old dirty air that currently recycles inside your room and push it outside. This is how it introduces fresh air from outside and sets that in the room. This way, the air is able to circulate back and forth from top keeping your birds happy & healthy.

But as you can imagine, not all exhaust fans are created equal so we must continue to explore the best options out there for your space. Depending on the size and shape layout of your farm you would select one over another. A small fan is inadequate for recirculating pure air. One that is too large can quickly chill your birds or cause cold draftnessurgence in smaller species. Well, so balance is key here.

By keeping your bird out of danger, a commercial exhaust fan contributes to the smoother running of the farm. You might be wondering how this works. An exhaust fan is the most appropriate kind of ventilation because it makes sure you will always maintain a perfect temperature while keeping excellent air quality too:Your birds grow fester, they eat more food an even lay more eggs!

If your chicken coop is perhaps overheating up or getting far too drafty, whilst to you this would be a sign the hens need air vents placed open wider, in fact may well mean just stressing them out and making life harder. This obviously will inhibit them from growing, produce less eggs and be terrible news for your farm. In the winter when your coop is too cold birds can get sick or even frostbitten. Plus the need temp is held above by a good exhaust fan mixed with if essential air.

Disease: Newly created disease in your flock will be greatly reduced but having the air inside fresh and clean from an exhaust fan means less birds falling sick. What makes this so important is birds that are healthier generally mean less replacements, and the fewer number of replacements you have to make-well...that adds up -It saves some cash!

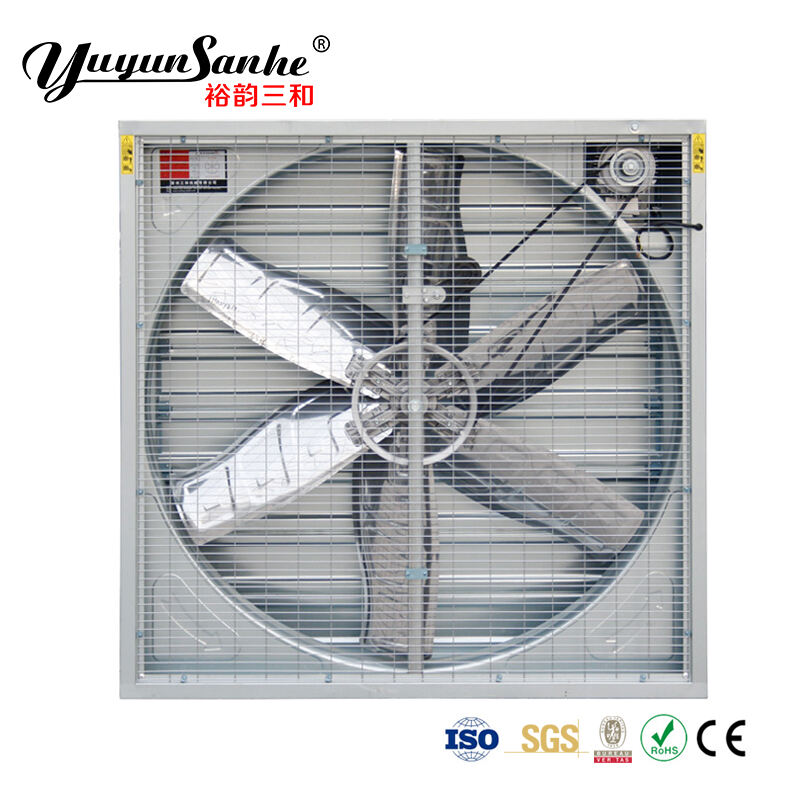

poultry farm exhaust fan We are the top domestic manufacturer of ventilation equipment. Our production equipment is controlled digitally and we require that each error be less than 0.03mm in order to guarantee an absolute interchangeability. The majority of parts we manufacture ourselves and reduce the cost of processing and ensuring the quality of the product and leading the world in price performance. Our design team is super-efficient and is comprised of more than 20 professionals with over 20 years of design and manufacturing knowledge. All products have been improved from drawing to production from drawing to production and from drawing improvement into mass production to make sure that the defect rate is zero. Our experienced sales staff can plan your purchase with you, reducing the cost of transport and boost profit margins. The perfect after-sales support system allows our customers to have no worry about their purchases.

We have a poultry farm exhaust fan manufacturing machine that is efficient and automation. The cooling pads produced are corrugated uniformly, have strong structural strength and can absorb water efficiently. The corrugated papers have been specially treated to have high durability and resistance to corrosion. It also resists mildew. Water absorption and permeability are excellent, no water drift, will ensure that water is evenly absorbed by the entire cooling pad wall. The stereoscopic design is specific and provides the biggest surface area for evaporation to exchange heat between water and air, the efficiency of evaporation is high. Safety Energy saving Environmental protection, cost-effective and applicable. Standard production 600mm wide cooling pad requires at least 86 sheets. Frames made of aluminum or stainless steel frame galvanized sheet frame and PVC frame are options.

All fan plates are constructed from hot dip galvanized sheets of 275g/m2, which we directly purchase from "poultry farm exhaust fan" the most well-known Chinese steel manufacturer. This is not just a guarantee of the quality of our products, but also reduces the cost of production. Mitsuboshi belt is imported from Japan to ensure quality and long-lasting service. Krupp 430BA Stainless Steel blades, with an enormous air volume and great efficiency. No deformation, no dirt, stunning, durable. The 304 2B Stainless Steel Blades can be customized. Belt pulleys and flanges are constructed of high-strength aluminum and magnesium alloy by die-casting, light weight and vibration-free, as well as high strength and no breakage. All components are manufactured using CNC streamlined production, excellent quality control, attractive appearance leading the market. Yuyun Sanhe, Siemens, WEG, ABB, and WEG motors are readily available. The frequency and voltage can be adjusted.

Our company is equipped with the latest Feed Silo Production Equipment that is extremely automated and precise. The silo is composed of hot-dip galvanized sheets weighing 275g/m2 and all screws are made of 8.8-level high-strength hot-dip galvanized bolts, which are poultry farm exhaust fan, corrosion-resistant, high-temperature resistance, high strength and have a long service life and can withstand a strong storm. The silo consists of the silo, silo lid mounting ladder, silo leg. The parts are produced by using precise molds and the latest laser technology in complete compliance with the drawing design. They are then subjected quality tests to ensure that they are standard and accurate.

Sophie Dong

Sophie Dong sanhe2@wfsanhe.com

sanhe2@wfsanhe.com  +86-13780857291

+86-13780857291 Lorna Gao

Lorna Gao sanhe7@wfsanhe.com

sanhe7@wfsanhe.com  +86-19806216802

+86-19806216802